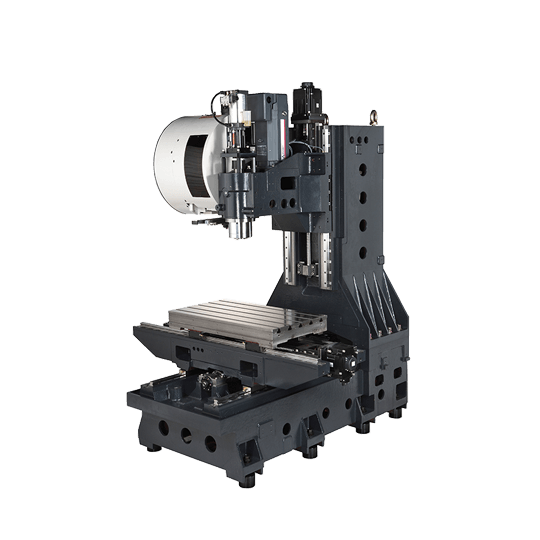

Vertical Machining Center

CNV-850

X:850 / Y:520 / Z:520 (mm)

The cast iron construction was designed using "Finite Element Analysis (FEA) and Advanced 3D Software and is extremely rigid and provides extremely accurate machining capabilities as well as high metal removal rates.

The CNV series was ergonomically designed from the movable control panel to chip disposal and many other design features to reduce operator fatigue and increase working efficiency.

Machine Specification

| Item | Unit | CNV-850 |

|---|---|---|

| Travel | ||

| X axis travel | mm (in) | 850 (33.4") |

| Y axis travel | mm (in) | 520 (20.4") |

| Z axis travel | mm (in) | 520 (20.4") |

| Distance from spindle nose to table surface | mm (in) | 110~630 (43" ~ 24.8") |

| Distance from spindle center to column | mm (in) | 630 (24.8") |

| Table | ||

| Table dimension | mm (in) | 950 × 520 (37.4" x 20.4") |

| Max. loading weight | kg (lb) | 500 (1,102) |

| T-slots (W x No. x P) | mm (in) | 18 x 5 x 100 (0.7" x 5 x 3.9") |

| Spindle | ||

| Spindle speed (OPT) | rpm | 8,000 (10,000 / 12,000 / 15,000) |

| Spindle motor | kW (HP) | 7.5 / 11 (15) |

| Spindle taper | type | 7/24 taper No.40 |

| Automatic Tool Changer | ||

| ATC type (OPT) | type | Arm type (Carrousel) |

| Tool shank | type | BT-40 |

| Pull stud | type | P-40T (45°) |

| Tool storage capacity (OPT) | pcs. | 24 (20) |

| Max. tool diameter | mm (in) | Ø80 (Ø3.1") |

| Max. tool diameter (Adjacent empty) | mm (in) | Ø150 (Ø5.9") |

| Max. tool length | mm (in) | 250 (9.8") |

| Max. tool weight | kg (lb) | 7 (15) |

| Tool change time (Tool to Tool) | sec. | 2.5 |

| Tool change time (Chip to Chip) | sec. | 7 |

| Feedrate | ||

| Rapid feedrate (X / Y / Z) | m (in) /min | 30 / 30 / 30 (1,181.1 / 1,181.1 / 1,181.1) |

| Cutting feedrate | mm (in) /min | 10,000 (393.7) |

| Other | ||

| Floor plan (W × D) | mm (in) | 2,930 × 2,260 (115" x 88") |

| Machine weight | kg (lb) | 5,000 (11,023) |

| Max. machine hight | mm (in) | 2,680 (105") |

| Air source | kg/cm2 (PSI) | 6~8 (85~113) |

| Power capacity | KVA | 15 |

Related Products

Need Inquire ?

If you need more information or quotation about this product, Our sales representative will reply as soon as possible