5 Axis Machining Center

5 Axis Machining Center for High-Precision Manufacturing

A 5 Axis Machining Center enables simultaneous multi-directional cutting, going beyond traditional 3-axis capabilities. With additional rotational axes, it delivers exceptional flexibility and access to complex geometries—ideal for precision parts in aerospace, medical, and automotive industries.

Why 5 Axis CNC Machining Outperforms 3 Axis VMCs

Compared to standard 3-axis setups, 5 Axis CNC Machining reduces the need for manual repositioning and multiple fixturing steps. This saves significant time and labor while improving accuracy.

1. Reduce setup time by up to 50% and cut total machining time by 30%.

2. Achieve tighter tolerances on complex surfaces in a single setup.

Simultaneous 5 Axis CNC Milling enhances surface finish quality and tool life—particularly valuable in high-value, low-volume production environments.

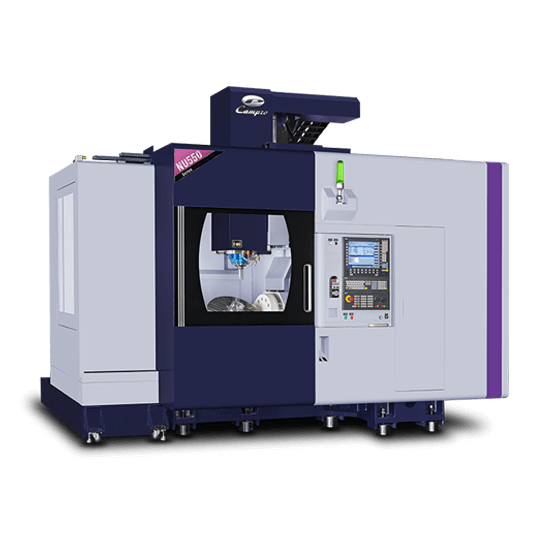

NU Series – Advanced 5 Axis CNC Machining Centers by Campro

Campro’s NU Series offers flexible configurations to match diverse manufacturing needs:

• Table-Table (NU 170C / NU 255C / NU 400C / NU 550 (Monoblock Column)): Compact layout with 360° rotary table

• Head-Table (NU 630 (Traveling Column) / NU 1250): High accessibility, smaller footprint

The NU Series is engineered to minimize machine interference, improve tool reach, and optimize space usage.

Applications and Measurable Impact

• Aerospace: 30% faster completion of turbine blade profiles

• Automotive: Improved precision in gear housing production

• Medical: Achieved ±0.005 mm tolerance in orthopedic components

• Job Shops: Reduced fixture cost by 40% in multi-face part machining

As a trusted 5 Axis Machining Center Manufacturer, Campro delivers globally supported solutions backed by proven field performance.

We help manufacturers enhance efficiency, reduce costs, and scale operations—powered by high-rigidity designs and modular configurations.

NU Series

Need Inquire ?

If you need more information or quotation about this product, Our sales representative will reply as soon as possible