Intelligent Ways - IIoT System Enhance Your CNC Operations

Proven Excellence Through Customer Testimonials

The staff members of Campro R&D Department have more than 10 years of machine tool R&D experience. Customer needs are our foremost priority. With this in mind, we built an R&D team that possesses a unique and innovative spirit. 5% of our annual turnover is allocated yearly as research funding, to promote independent R&D capabilities and improve the precision and functionality of various CNC machine tools. Whether it is a belt-driven spindle or a direct-drive built-in spindle of high speed and high torque, we can provide customization according to customer needs. We have also successfully developed the “All-Geared Gear Head”, and brought its characteristic of heavy cutting capacity into full play.

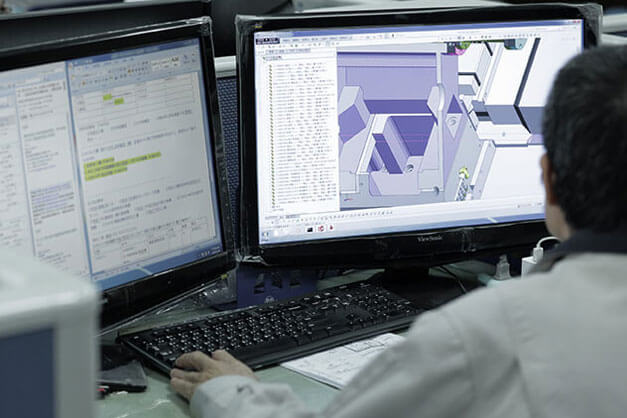

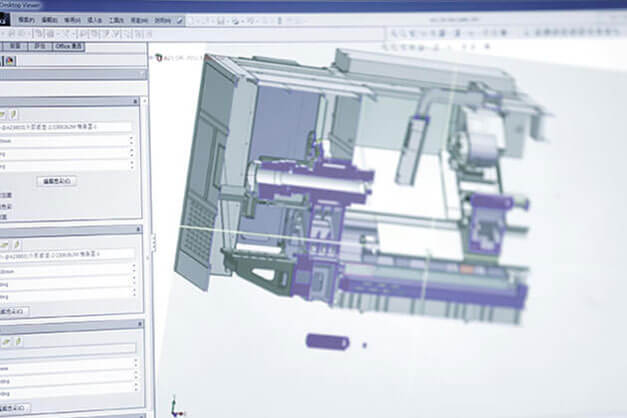

R&D Design Tools

Precise simulation at the design stage “Cam” and “Pro” are short for “Computer-aided manufacturing” and “Professional” respectively. Beginning with its name, Campro conveys its intentions to achieve the most “professional” performance in the manufacturing of high-end CNC machine tools

Product Development Process

CPMS PDM and ERP System Managed Picture Files / Information

-

Taiwan / Shanghai plant information collated under the Parent Company

-

TRetrieval and storage of picture files and information are strictly regulated

End User Distributor

Market Demand Analysis

Product Development

Component Based Design

Trial Assembly

Put Into Mass Production

Design Improvement

Need Inquire ?

If you need more information or quotation about this product, Our sales representative will reply as soon as possible