Double Column Machining Center

When evaluating your next machine investment, consider two structural types: the traditional C-frame and the larger CNC Double Column (also known as bridge or gantry type). A Double Column Machining Center offers enhanced rigidity and stability for large workpieces, featuring two columns that support a moving cross-slide, spindle, and ram assembly. Compared to C-frame machines, double column types are ideal for high-precision heavy-duty machining.

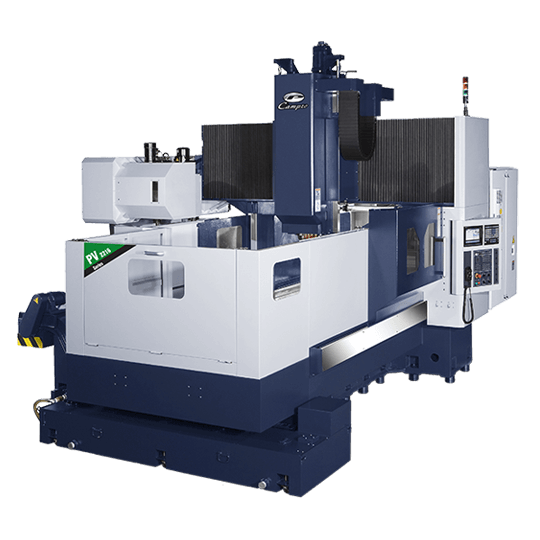

Campro’s Double Column Machining Center lineup includes the PV Series, a bridge-type CNC model built with a fixed gantry and moving table. This design separates X- and Y-axis movement for greater cutting accuracy. With travel sizes up to 5,200 mm × 2,600 mm, the PV Series is engineered for rigidity, high-speed performance, and machining flexibility.

Previously available as two series, Campro’s current focus is on the PV Series, optimized for die & mold, aerospace, and automotive parts production. Its powerful cutting capability handles aluminum, plastics, and composite materials with high-speed efficiency.

Key Features:

• Bridge structure bolted to the machine bed for extreme rigidity

• Compatible with high-torque spindles for aluminum, plastics, and light metals

• Ideal for high-speed machining and long-part processing

• Designed for durability in multi-shift production environments

Applications and Industries:

The Double Column Machining Center is widely used in:

• Aerospace: large frames, bulkheads, and structural parts

• Automotive: engine blocks, molds, and body panel dies

• Die & Mold: precision cavity cutting and base plate machining

Its high-load capacity and vibration resistance make it ideal for large part machining in heavy industries.

PV Series

Need Inquire ?

If you need more information or quotation about this product, Our sales representative will reply as soon as possible