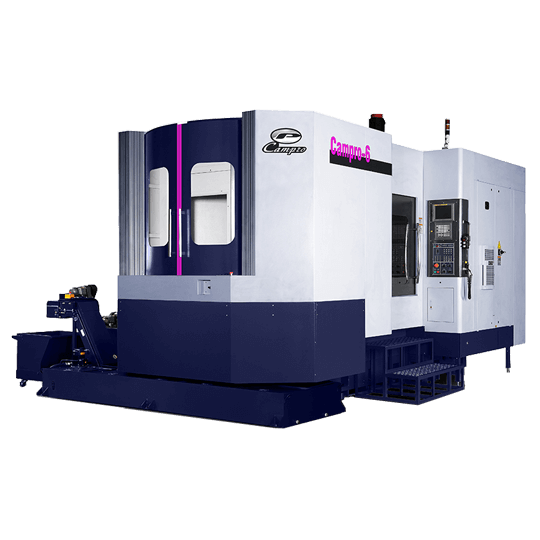

Horizontal Machining Center

CAMPRO 6

X:1000 / Y:850 / Z:950 (mm)

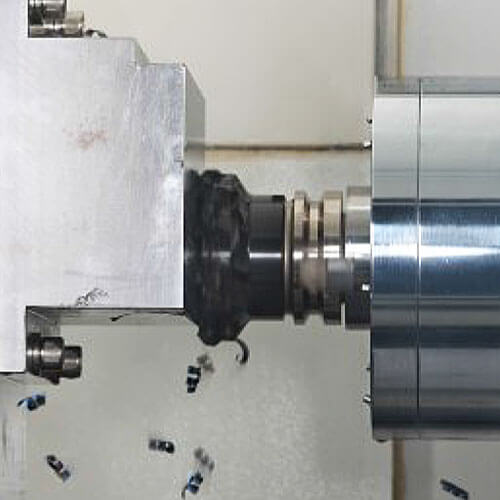

The Campro 6 CNC Horizontal Machining Center offers No. 50 taper on 6,000 rpm Gear Head spindle and also available on 10,000 rpm Built-in Motor spindle, with two-pallet changer integration and B-axis rotary table that are the best combination for high-volume production, the machine travels of 1,000 mm x 850 mm x 950 mm with dia. 630 mm table provides dia. 1,050mm x H 1,000 mm working range. The Campro 6 is ideal for large parts and tombstones metalworking applications.

Feature

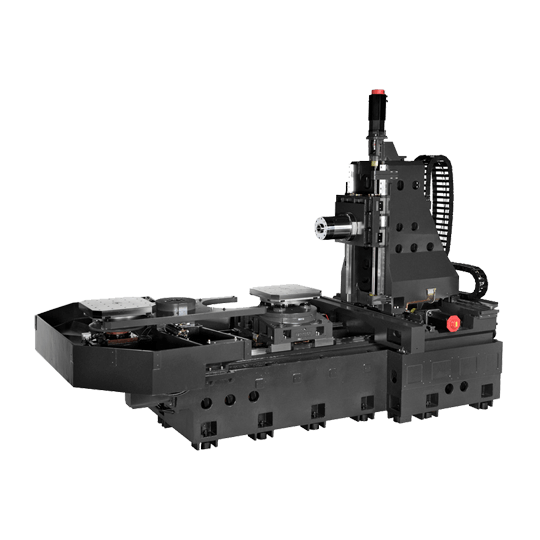

The high rigid and heavy loading linear guideways with roller type precision bearing on 3 axes ensuring stability and accuracy in long time machining.

Constructed with FC300 cast iron. T-shape one piece base and dual wall column are designed with rigid construction.

Stepped beam is structured effectively reduces torque created by spindle stock and cutting force.

Final laser inspection and ball bar testing ensure repeatability and positioning accuracy.

Machine Specification

| Item | Unit | CAMRPO 6 |

|---|---|---|

| Travel | ||

| X axis travel | mm (in) | 1,000 (39.3") |

| Y axis travel | mm (in) | 850 (33.4") |

| Z axis travel | mm (in) | 950 (37.4") |

| Spindle nose to table center | mm (in) | 150~1,100 (5.9" ~ 43.3") |

| Spindle center to table surface | mm (in) | 100~950 (3.9" ~ 37.4") |

| Table | ||

| Table dimension | mm (in) | 630 × 630 (24.8" x 24.8") |

| Screw spec. | type | M16 × 2P |

| Index of pallet | degree | 1° |

| Max. working range | mm (in) | Ø1,050 × H1,000 (Ø41.3" x H39.3") |

| Max. loading weight | kg (lb) | 1,000 (2,204) |

| Spindle | ||

| Spindle motor | kg (lb) | L: 15 / 22, H: 25 / 30 |

| Spindle speed | rpm | 10,000 |

| Spindle taper | type | 7/24 taper No.50 |

| Automatic Tool Changer | ||

| No. of tools | number | 40 |

| Max. tool weight | kg (lb) | 20 (44) |

| Max. tool length | mm (in) | 500 (19.6") |

| Max. tool diameter | mm (in) | Ø120 (Ø4.7") |

| Max. tool diameter (Adjacent empty) | mm (in) | Ø240 (Ø9.4") |

| Tool change time (Tool to Tool) | sec. | 3.5 |

| Tool change time (Chip to Chip) | sec. | 7 |

| Feedrate | ||

| Rapid feedrate (X/Y/Z) | m (in) /min | 36 / 36 / 36 (1,417.3 / 1,417.3 / 1,417.3) |

| Cutting feedrate | mm (in) /min | 10,000 (393.7) |

| Other | ||

| Floor plan (W×D) | mm (in) | 7,135 × 5,068 (280" x 199") |

| Machine weight | kg (lb) | 24,000 (52,910) |

| Max. machine hight | mm (in) | 3,550 (139") |

| Power capacity | KVA | 60 |

Need Inquire ?

If you need more information or quotation about this product, Our sales representative will reply as soon as possible